The predominant route to this salt is the extraction of tungsten ores, almost all of which are tungstates. Thus, the ores are treated with a base to give sodium tungstate, as illustrated in the case of wolframite:

Fe/MnWO4 + 2 NaOH + 2 H2O → Na2WO4•2H2O + Fe/Mn(OH)2

Scheelite is treated similarly using sodium carbonate.

Sodium tungstate can also be produced by treating tungsten carbide with a mixture of sodium nitrate and sodium hydroxide in a fusion process which overcomes the high exothermicity of the reaction involved.

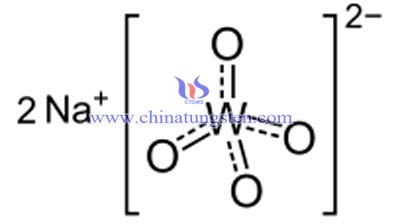

Several polymorphs of sodium tungstate are known, three at only one atmosphere pressure. They feature tetrahedral orthotungstate dianions but differ in the packing motif. The WO42− anion adopts a structure like sulfate (SO42−).

2015年7月20日星期一

Uses of Sodium Tungstate

Uses of Sodium Tungstate:

1、For the mordant, analytical reagents, catalysts, water treatment chemicals, manufacturing fireproof, waterproof material, and phosphorus tungstate, tungsten, boron salts.

2、For the manufacture of tungsten, tungsten acid, tungstate,etc.

3、For the mordant, pigments, dyes, inks.

4、 As a weighting agent for fabric by weavers. This product is used as textile assistants. And a mixture of tungsten acid, ammonium sulfate, ammonium phosphate and other components used in fiber fire and water. This kind of fibers can be made into fireproof rayon and rayon. It can also be used in tanning leather.

5、As anti-corrosion coating for electroplating.

6、As a co-solvent playing a role in reducing firing temperature and complementary color when introducing enamel pigment.

7、For petroleum and aerospace manufacturing industry, aerospace materials.

1、For the mordant, analytical reagents, catalysts, water treatment chemicals, manufacturing fireproof, waterproof material, and phosphorus tungstate, tungsten, boron salts.

2、For the manufacture of tungsten, tungsten acid, tungstate,etc.

3、For the mordant, pigments, dyes, inks.

4、 As a weighting agent for fabric by weavers. This product is used as textile assistants. And a mixture of tungsten acid, ammonium sulfate, ammonium phosphate and other components used in fiber fire and water. This kind of fibers can be made into fireproof rayon and rayon. It can also be used in tanning leather.

5、As anti-corrosion coating for electroplating.

6、As a co-solvent playing a role in reducing firing temperature and complementary color when introducing enamel pigment.

7、For petroleum and aerospace manufacturing industry, aerospace materials.

Sodium Tungstate

Names

IUPAC name Sodium tungstate

Identifiers

CAS Registry Number 13472-45-2

PubChem 26052

RTECS number YO7875000

Properties

Chemical formula Na2WO4

Molar mass 293.82 g·mol−1

Appearance white rhombohedral crystals

Density 4.179 g/cm3 (anhydrous)

3.25 g/cm3 (dihydrate)

Melting point 698 °C (1,288 °F; 971 K)

Solubility in water

57.5 g/100 mL (0 °C)

74.2 g/100 mL (25 °C)

96.9 g/100 mL (100 °C)

Solubility slightly soluble in ammonia insoluble in alcohol, acid

Structure

Crystal structure rhombic (anhydrous)

orthorhombic (dihydrate)

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

2014年4月22日星期二

about Lithium Tungstate

Lithium tungstate is the inorganic compound with the formula Li2WO4, appears white solid that is soluble in water. The compound is one of the several other tungstates, compounds that feature the tetrahedral WO42- anion.

Lithium tungstate is used to produce high density water solutions. This use was developed in the early 1990s to address issues with existing high density fluids such as toxicity, safety, and stability, It can safely be used in an indoor environment without a fume hood with only ordinary common sense safety precautions such as protective gloves and safety glasses.

The salt consists of tetrahedral coordinated Li and W content bridged by oxides. The solid undergoes phase transitions at high pressures, such that the coordination geometry at tungsten becomes octahedral.

Please visit our website www.tungsten-powder.com to get more information about tungsten related powders.

Applications of Tungsten Disulfide

Tungsten Disulfide whose chemical formula is WS2, can be used in high temperature and high pressure applications. It offers temperature resistance from -270º C to 650º C in normal atmosphere and from -188º C to 1316º C in Vacuum. Load bearing ability of coated film is extremely high at 300,000 psi. WS2 can also be used instead of molybdenum disulfide-MoS2.

The WS2 powder could be mixed with wet lubricants:

The tungsten disulfide powder can be mixed 1wt% to 15wt% (as users required) with grease or oil. This will enhance lubricity of the mixture and also improves High Temperature and Extreme Pressure properties of mixture. During the use, tungsten disulfide in the mixture will get coated on mating/moving parts, which in turn reduces friction and improves lubricity and load bearing ability for much longer cycles.

The tungsten disulfide powder can be coated by spraying (at 120 psi) the substrate with dry & cool pneumatic air. It does not require any binders and spraying can be done at normal room temperature. Coated film will be 0.5 um thick. In an alternative application method, tungsten disulfide powder could be mixed with Propyl alcohol and this paste could be buffed to the substrate.

Visit our website www.tungsten-powder.com to get more information.

Storage of Tungsten Powder

There are several requirements on storage of tungsten powder as following:

*Should be stored in shady, cool and ventilated warehouse.

*Keep far away from fire, heat source and acid.

*Smoking in the workplace is absolutely prohibit.

*Should be available fire fighting equipment such as extinguisher .

*Stored in vacuum encapsulation in case of being oxidized.

Please visit our website www.tungsten-powder.com to get more information about tungsten powder storage.

*Should be stored in shady, cool and ventilated warehouse.

*Keep far away from fire, heat source and acid.

*Smoking in the workplace is absolutely prohibit.

*Should be available fire fighting equipment such as extinguisher .

*Stored in vacuum encapsulation in case of being oxidized.

Please visit our website www.tungsten-powder.com to get more information about tungsten powder storage.

2014年4月15日星期二

New Opened Tungsten Mine in UK

As reported, tungsten mine in UK opened recently. Exact information as following:

"The £123 million Hemerdon project, near Plymouth, Devon, is reportedly the third largest tungsten resource in the world.

When complete the mine will feature an 850m x 450 m open cast pit extending to a depth of 200 m, together with a processing plant and integrated mine waste facility.

Production is expected to start in 2015 and is scheduled to produce 3,450 tonnes of tungsten concentrate annually – equivalent to approximately 3.5% of global forecast demand – providing security of supply for tungsten and valuable export revenue for the UK, according to Wolf Minerals."

More information about tungsten concentrate or tungsten related powder, please visit: www.tungsten-powder.com

订阅:

博文 (Atom)